Vapor Blast Machinery Specifications

Vapor Blast Manufacturing Company

3025 W. Atkinson Ave. Milwaukee, WI 53209

Ph. (414) 871-6500 Fax (414)-871-7683 Toll Free: 888-834-6500 E-Mail:sales@vaporblast.com

Copyright © 2011 Vapor Blast Manufacturing Co. All rights reserved.

Site Maintained By Blazing Mind Media

| ||||||

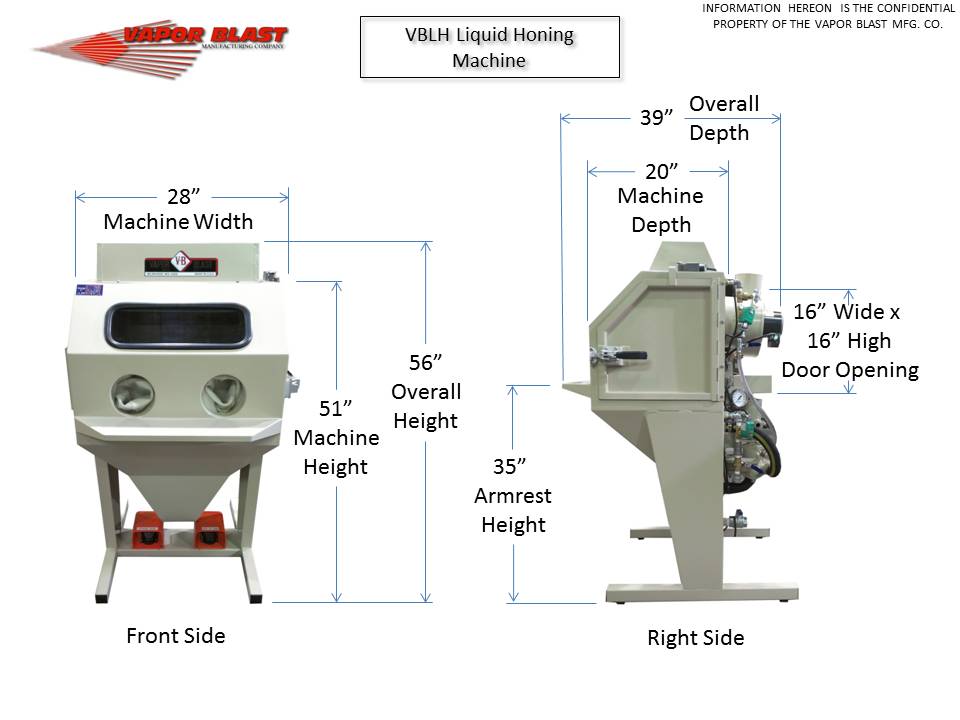

VBLH "Sit N' Hone" SERIES

Modern design accomodates operator convienences and production efficiency.

Operator fatigue is reduced with the "Sit N' Hone" operation. Natural arm rest, right side loading,

foot actuated blast gun control, lightweight gun, and conveniently located light and fan switches,

air pressure gauge and air pressure regulator with in arm's reach help increase operator efficiency.

Equipped with filtered exhaust system and only requiring standard shop air, water supply,

standard 120v power outlet, exhaust and drain facilities.

- Item:

VBLH 2820 - Sit N' Hone

VBLH 2820 - Sit N' Hone

- Item Name:

Vapor Blast Liquid Honing

Vapor Blast Liquid Honing

- Interior Dimensions:

28'' x 20'' x 20"

28'' x 20'' x 20"

- Overall Dimensions:

32" x 39" x 56"

32" x 39" x 56"

- Door Opening Height:

16"

16"

- Door Opening With:

16"

16"

- Standard Number Of Doors:

1

1

- Carbide Nozzle, Diameter:

3/8''

3/8''

- Stainless Steel Air Jet, Diameter:

3/16"

3/16"

- Slurry Pump Motor:

3/4 HP

3/4 HP

- Exhaust Fan Motor:

1/12 HP

1/12 HP

STANDARD FEATURES

* STAINLESS STEEL CABINET AND HOPPER, NON-FERROUS INTERIOR PIPING

STAINLESS STEEL CABINET AND HOPPER, NON-FERROUS INTERIOR PIPING

* NEMA I, NEC, 115 VOLT, SINGLE PHASE, 60 HERTZ PRIMARY POWER SUPPLY

NEMA I, NEC, 115 VOLT, SINGLE PHASE, 60 HERTZ PRIMARY POWER SUPPLY

* CABINET LIGHTING, THREE (3) 15 WATT FLUORESCENT TUBES

CABINET LIGHTING, THREE (3) 15 WATT FLUORESCENT TUBES

* FILTERED EXHAUST SYSTEM WITH DIRECT DRIVE ELECTRIC MOTOR

FILTERED EXHAUST SYSTEM WITH DIRECT DRIVE ELECTRIC MOTOR

* VAPOR BLAST SLURRY PUMP ASSEMBLY SUPPLIES THE BLAST NOZZLE AND UNIFORMLY SUSPENDS ABRASIVE MEDIA IN THE SLURRY HOPPER. VAPOR BLAST PUMPS PRODUCE THE EXACT VOLUME FOR TOP PROCESS PERFORMANCE ...

VAPOR BLAST SLURRY PUMP ASSEMBLY SUPPLIES THE BLAST NOZZLE AND UNIFORMLY SUSPENDS ABRASIVE MEDIA IN THE SLURRY HOPPER. VAPOR BLAST PUMPS PRODUCE THE EXACT VOLUME FOR TOP PROCESS PERFORMANCE ...

* 6'' X 18'' OPERATOR OBSERVATION WINDOW ... EASILY REPLACED SAFETY WINDOW; CONVENIENCE TOOLS

6'' X 18'' OPERATOR OBSERVATION WINDOW ... EASILY REPLACED SAFETY WINDOW; CONVENIENCE TOOLS

* PUMP FLUSHING SYSTEM (FRESH WATER) WITH SHUT-OFF VALVE

PUMP FLUSHING SYSTEM (FRESH WATER) WITH SHUT-OFF VALVE

* OBSERVATION WINDOW SPRAY WASH SYSTEM OPERATED BY ELECTRIC FOOT SWITCH

OBSERVATION WINDOW SPRAY WASH SYSTEM OPERATED BY ELECTRIC FOOT SWITCH

* SIDE LOADING DOOR, HINGED, FITTED WITH ELECTRICAL INTERLOCK TO SHUT DOWN PROCESS OPERATION

SIDE LOADING DOOR, HINGED, FITTED WITH ELECTRICAL INTERLOCK TO SHUT DOWN PROCESS OPERATION

* OPERATOR ARMPORTS WITH CONVENIENT ARMREST, QUICK RELEASE CLOTH-LINED GLOVES

OPERATOR ARMPORTS WITH CONVENIENT ARMREST, QUICK RELEASE CLOTH-LINED GLOVES

* TYPE “S” BLAST GUN WITH CARBIDE NOZZLE STAINLESS STEEL AIR JET

TYPE “S” BLAST GUN WITH CARBIDE NOZZLE STAINLESS STEEL AIR JET

* SINGLE PROCESS CONTROL, VIA ELECTRIC FOOT SWITCH, ACTUATING SOLENOID CONTROLLED COMPRESSED

SINGLE PROCESS CONTROL, VIA ELECTRIC FOOT SWITCH, ACTUATING SOLENOID CONTROLLED COMPRESSED

* AIR GAGE AT OPERATOR STATION; COMPRESSED AIR INTAKE FITTED WITH OSHA APPROVED AIR LOCK-OUT/BY

AIR GAGE AT OPERATOR STATION; COMPRESSED AIR INTAKE FITTED WITH OSHA APPROVED AIR LOCK-OUT/BY

* PERFORATED METAL WORK PLATFORM, WEAR COATED TO CUSHION PART HANDLING (500-LB CAPACITY)

PERFORATED METAL WORK PLATFORM, WEAR COATED TO CUSHION PART HANDLING (500-LB CAPACITY)

* OPERATOR CHAIR, SWIVEL TYPE, WITH VINYL SEAT AND BACK SUPPORT

OPERATOR CHAIR, SWIVEL TYPE, WITH VINYL SEAT AND BACK SUPPORT

* MACHINE SPECIFICATIONS IN COMPLIANCE WITH OSHA REGULATIONS

MACHINE SPECIFICATIONS IN COMPLIANCE WITH OSHA REGULATIONS

* MACHINE PAINTED WITH HIGH GRADE INDUSTRIAL ENAMEL (TAN)

MACHINE PAINTED WITH HIGH GRADE INDUSTRIAL ENAMEL (TAN)

MACHINE OPTIONS AND ACCESSORIES

* SETTLING TANK (PORTABLE INDEPENDENT UNIT)

SETTLING TANK (PORTABLE INDEPENDENT UNIT)

TANK INCLUDES WEIR SYSTEM TO SETTLE OUT AND COLLECT ABRASIVE. AN OVERFLOW DRAIN FITTING CAN BE CONNECTED TO BUYER’S SEWER TO DISCHARGE THE SEPARATED WATER. THIS TANK RECEIVES THE WATER DISCHARGED FROM THE CABINET WINDOW WASH.

* SLURRY EVACUATOR SYSTEM

SLURRY EVACUATOR SYSTEM

AN EFFICIENT SYSTEM THAT TOTALLY EVACUATES HOPPER SLURRY CONTENTS VIA AN ADJUSTABLE PNEUMATIC OPERATED DEVICE. THE SLURRY IS CONVEYED TO BUYER’S DISPOSAL CONTAINER WITH 8’ DISCHARGE LINE.

Model 2820